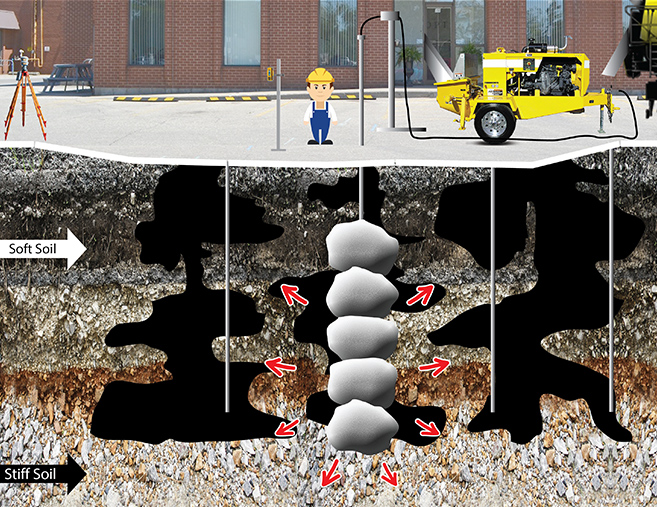

is the Soil Improvement to increase loading capacity to the soil and stop the soil layer subsidence under the load by compacting Low Slum Concrete with pressure into the soft soil layer the replace the concrete with mentioned soil layer that increase the density and soil mass of the soil layer or loading capacity while nearby soil would be also compacted for more density with the concrete state that has low slum and bulky spread without inserting into spaces and cracks of soil layer. From these mentioned factors, these would increase the efficiency of soil layer grinding, pressing to bleed the water, space compressing efficiently

Advantages of the Soft Soil layer Improvement by using Compaction Grout method

- Low cost material that use less budget in Soft Soil layer Improvement for large and deep area compared with other methods

- Simple and no need of any large tools in working process that easily access to the narrow working sites

- There is a completion inspection process of Soil layer Improvement by measuring the pumped material’s volume and measuring the pressure during the pumping which means the soil layer resistance.

- Compacting can be performed with more than 20 meters depth

Compaction Grout

( Low-mobility Concrete )

Compaction Grout process

Test soil condition with CPT (Cone Penetration Test) in order to perceive capacity on load supporting of each soil horizon prior evaluating characteristics of repairing referring the depth of grouting, quantity of materials used in each point, and distance of each point.

Soil Condition Test

กDetermine distance of each point demanded to be pumped with general distance ranged from 2-3 meters approximately based on characteristics of structure and soil condition of foundation.

Concrete Coring Work Ø 3 Inches

Install casing with the depth obtained from the result of soil condition test.

Install Pressure Gauge

in order to measure soil resistance and materials transmission cable whereas grouting machine can be located away from concrete grouting machine around 50 meters.

Install and plan concrete

consisted of concrete mixer, concrete grouting machine, and materials storage area requiring the approximate area of 10x10 meters.

Grout Low Slum Concrete or concrete with slump of 50±10 millimeters (Slump Test) whereas completeness of concrete grouting can be evaluated and controlled by considering on quantity of grouted concrete and occurred pressure while grouting. This is considered as Soil Resistance referring to increasing loading capacity.

Grout concrete and measure structure leveling by using Laser Level.

Pull up CASING pile with hydraulic in order to grout materials in the next soil horizon.

PU DEEP GROUTING is grouting polyurethane in clay soil horizon in order to improve soil condition and capacity on load support of soil horizon. Polyurethane will expand to compress soil horizon at such depth tightly as well as replace gap or hole in soil horizon.

Principles of Clay Soil Horizon Improvement by UsingPU Deep Grouting

• With capacity on 10-time expansion of polyurethane, it can replace gaps in soil horizon and compress nearby soil to have higher level of density. • Rapid hardening within 10-15 second is another outstanding property of polyurethane that can control distribution of polyurethane to be in demanded area.

• It helps to reduce effects caused by compression due to dehydration of soil as well as contraction and expansion of soil.

• Polyurethane is able to insert and attach Non Cohecive soil.

• Polyurethane will replace gaps or holes in soil horizon.

• Clay soil horizon can be improved by increasing shear resistance whereas materials will be grouted in pressure bulb of the point that will be affected by shear of upper structure load.

PU Deep Grouting

PU DEEP GROUTING Procedures

Drill concrete as a hole with the dimension of 15 millimeters to the soil horizon under concrete foundation by using rotary hammer before installing materials pipeline with the diameter of 15 millimeters for conveying and grouting materials to soil horizon for grouting.

Install hydraulic material pipeline leveling set in order to grout materials in different levels continuously.

Grout materials with installation of Laser Level in order to measure structure leveling whereas the obtained value is in millimeter unit.